Co-creating an Eco-efficient Automotive Lighting Manufacturing Ecosystem: Osram and DP Patterning Collaborate to Advance Smart LED Control and Signifi

2025-11-10

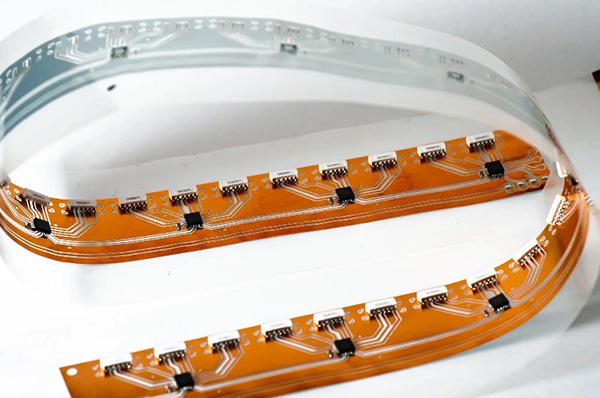

The global leader in lighting and sensing innovation, SIMS (SIX: AMS), and DP Pattern, jointly announced today the launch of a demonstration model showcasing the future development direction of automotive lighting systems. The demonstration model uses a single-layer flexible printed circuit board to replace traditional complex multi-layer designs, and according to the Fraunhofer Life Cycle Assessment report, it can reduce CO2 emissions by up to 98% in the production of structured processes compared to chemical wet etching processes. This demonstration model combines the dry circuit board manufacturing process of DP Pattern with the advantages of the AS1163 LED driver from AMS Osram. It not only presents innovative technological concepts, but also has broad practical potential, which can be easily applied to flexible circuit board scenarios such as automotive interior and exterior lighting and intelligent surfaces.

Demonstration model showcasing the conceptual possibilities of flexible circuit boards in automotive lighting applications

The Open Systems Protocol (OSP) of AMS Osram brings higher degrees of freedom to design and effectively reduces costs. The new demonstration model adopts the protocol plus the chemical free dry process of Swedish technology partner DP Pattern, demonstrating the potential for developing more sustainable solutions in the future.

This demonstration model can connect the LED, sensors, and actuators inside the car through a simple continuous line, achieving independent control of hundreds of light points. The independent intelligent driver (SAID) AS1163 enables low to medium power LEDs to be directly connected to the OSP network without the need for an external local microcontroller. This feature makes flexible and even single-layer circuit boards an ideal choice for creating ultra-thin and compact lighting modules.

This demonstration model reveals the future trend of lighting networks: subtraction in chemical processes and complexity, and addition in the degrees of freedom of single-layer design, "emphasized Andrea Maria Saraceno, an application engineer at Amess Osram.

Compared to traditional electronic circuit technologies that use etching grooves and silver paste printing, DP Patterning's dry patterning (DPP) technology is a unique patented dry process that does not require water or involve harmful chemicals, and can be imagined as precise dry cutting of metal coatings. This process does not generate chemical wastewater, leaving only dry and recyclable metal residues. In addition, this technology synchronously reduces energy consumption and process complexity. According to the Fraunhofer Life Cycle Assessment report, DPP technology can reduce carbon footprint by up to 98% compared to wet etching in structured processes.

The demonstration model jointly developed by AMS Osram and DP Pattern uses a single-layer flexible printed circuit board (FPCB) instead of traditional complex multi-layer designs

For car interiors, this technology brings greater potential for ambient lighting and intelligent surface design. Whether it's slender edge light strips or large-area curved light strips, they can achieve thinner and more flexible system integration. This technology also brings positive impacts to society and the environment: it not only effectively reduces energy consumption and eliminates wastewater pollution, but also supports localized production, thereby shortening the supply chain.

Please click here to learn more about the AMS Osram Open Systems Protocol (OSP).

DP Pattern will showcase the demonstration model at booth B2/506 of the International Electronic Production Equipment Expo (productronica) held at the Munich Exhibition Center in Germany from November 18th to 21st, 2025.

Note 1: Data Driven Sustainability Management, Gentherm Fraunhofer Collaboration Project | BPS Academy Report - June 1, 2022.

The scope of this life cycle assessment research focuses on structured processes and only compares different process steps. The system boundary does not include the same downstream processes, recycling, infrastructure, and scrap disposal links.