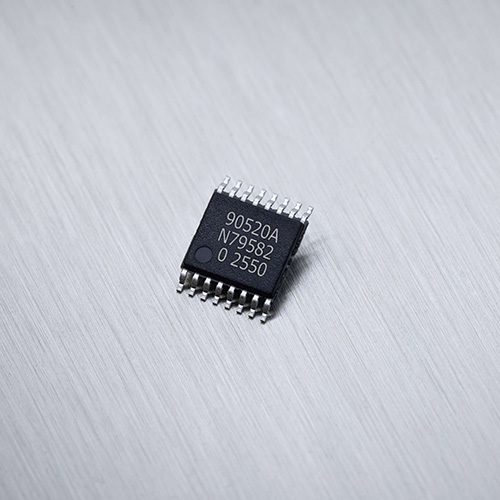

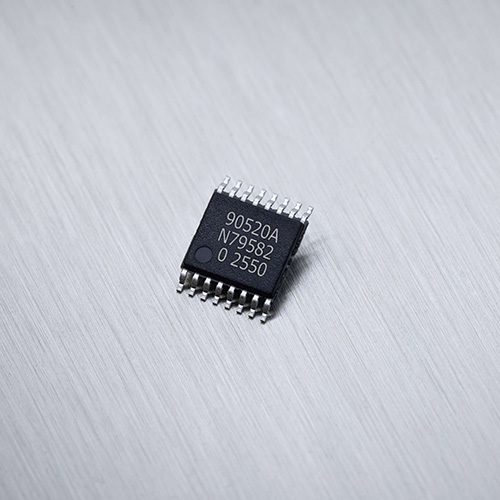

Melexis, a global microelectronics engineering company, announced the launch of an inductive encoder chip with 22 bit high resolution - MLX90520. This market benchmark product can perfectly adapt to rotating and linear motion scenarios, fully meeting the high-precision and cost-effective position detection needs of robots and large mechanical joints with diameters ranging from 20 to 200 millimeters.

Accurate position sensing of mechanical joints is crucial for achieving fast, repeatable, and safe operations in robots, automation systems, and construction and agricultural machinery. For a long time, optical encoders have dominated this field. However, with the urgent market demand for improving manufacturing efficiency, enhancing system reliability, and reducing production costs, the industry is pushing to explore more practical alternative solutions.

MLX90520 is an encoder chip with 22 bit high-precision resolution that provides low-noise, zero delay inductive position detection for rotational and linear motion (up to 400mm). This helps to achieve safe, repeatable, and precise control of large robotic arms, linear actuators, and other rotating components. Compared to traditional optical encoders, MLX90520 has significant advantages in size and robustness, and also provides SPI or SSI output interfaces to meet diverse application requirements.

In large-scale axial application scenarios, the ultra-thin module based on MLX90520 (including IC, PCB, and target block, with a thickness of less than 3 millimeters) creates the possibility for developing more compact and simplified mechanical components. Compared with optical or magnetic encoder schemes that require large magnets, this module has significant advantages. Inductive sensors themselves have excellent resistance to dust and other pollutants, which can effectively ensure the reliability of robots during long-term operation. In addition, the integration of onboard digital processing and system level compliance up to SIL 3 further enhance functional safety and provide assurance for operational safety.

In addition to achieving precise and repeatable operations, inductive sensors also have significant cost advantages compared to traditional optical solutions. This is mainly attributed to the inductive encoder MLX90520, which has a lower initial component cost than optical encoders, and a simpler system integration and development process - the device only requires a small number of parameters to be configured before operation and can be put into use.

Lorenzo Lugani, Product Line Director of Mailaixin, said, "With the inductive MLX90520, we provide a high-quality alternative to optical encoders for the robotics industry. It provides high performance while also offering highly competitive prices and a simple development process, which can help engineers expand application boundaries. At present, the device has received positive feedback from multiple companies and will help our customers achieve success in the market in the future