6.8 μ s rapid response+high voltage resistance! ABLIC releases new safety standard for voltage detector IC reshaping system

2025-05-29

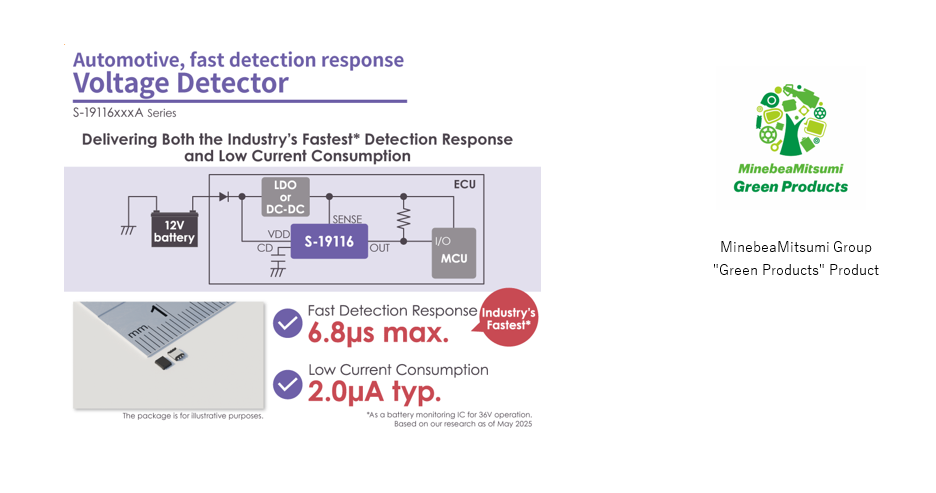

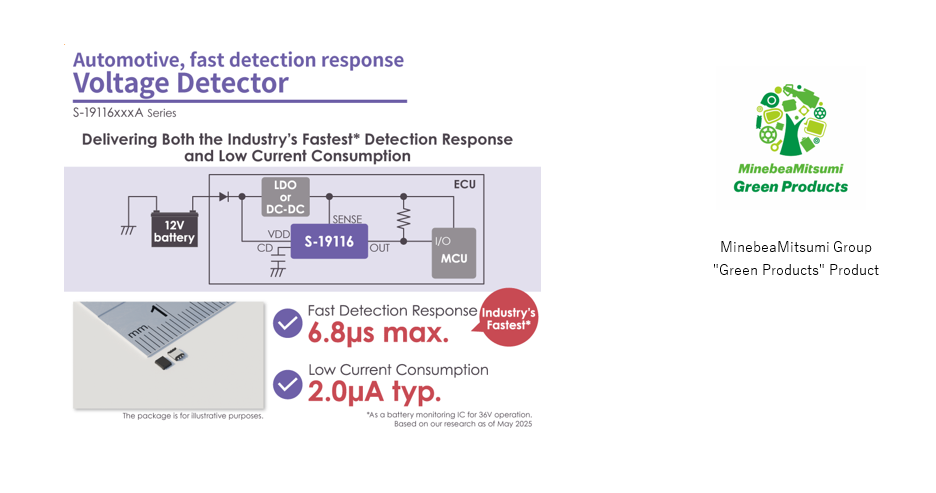

With the popularization of 800V high-voltage platforms, the risk of overvoltage in vehicle electronic systems has sharply increased. The traditional voltage detection IC faces the technical paradox of "increasing speed inevitably increases power consumption" - for every 1 μ s increase in response speed, power consumption often increases by more than 5 μ A. ABLIC (a subsidiary of Meibeiya Sanmei) has made a breakthrough by launching the S-19116 series voltage detector IC, which achieves a revolutionary upgrade in safety and energy efficiency with the industry's fastest overvoltage response of 6.8 μ s and ultra-low operating current of 2.0 μ A. It builds a safety defense line for core systems such as BMS and OBC.

Product Function: Redefine the Boundary of Vehicle Safety Monitoring

Functional dimension

|

technical realization

|

user value

|

safety protection

|

-30V~45V wide voltage input range

|

Compatible with 12V/48V/800V multi voltage platforms

|

Rapid response

|

Overvoltage detection response time ≤ 6.8us

|

1000 times faster than fuses, avoiding electrical damage

|

Energy efficiency breakthrough

|

Working current 2.0 μ A (typical value)

|

Five years of initial electricity is equivalent to expanding battery capacity by 596

|

space optimization

|

HSNT-6 package (1.96x2.46x0.5mm)

|

PCB area reduced by 70% compared to traditional solutions

|

Technological breakthrough: synchronous achievement of dual limit parameters

1. Resolving the Paradox of Speed and Power Consumption

Dynamic charge injection technology: By precisely controlling the timing of the comparator switch, the response delay is compressed to 6.8 μ s (competitor average of 15 μ s), while avoiding the power consumption surge caused by traditional acceleration circuits

Subthreshold bias design: The core comparator operates in the low voltage range of 0.8V, reducing current loss to nanoampere level, and the total power consumption is only one-third of that of competitors

2. Upgrading adaptability to high-pressure environments

Adaptive gate drive: maintains functional integrity even under -30V reverse voltage surge (AEC-Q100 Grade 0 certified)

45V voltage withstand layer optimization: adopting deep groove isolation technology, the surge resistance ability reaches

3 times that of ISO 7637-2 standard

Comparative analysis of competitors: performance crushing and cost balance

parameter

|

ABLIC S-19116

|

TI TPS3700

|

ADI LTC4366

|

Test conditions

|

Overvoltage response time

|

6.8μs (Max)

|

12μs (TyP)

|

|

Vov=36V 25°C

|

Working current

|

2.0μA (TyP)

|

6.5μA (TyP)

|

8μA (TyP)

|

Vcc=5V standby mode

|

Voltage endurance range

|

-30V~45V

|

-20V~40V

|

-25V~40V

|

-

|

Package Size

|

1.96x2.46mm

|

3.0x3.0mm

|

2.5x2.5mm

|

-

|

Unit price (thousand pieces)

|

$0.85

|

$0.92

|

S1.15

|

Q2 2025 vehicle specification quotation

|

Data source: ABLIC datasheet V1.0; TI/ADI official website specification sheet; Digi Key Quotation System

Industry Value: Cracking the Three Major Security Challenges of High Voltage Systems

1. Cascade failure caused by response delay

When the traditional solution responds with 15 μ s, the overvoltage impact of the 800V system can damage SiC modules worth $200. The 6.8 μ s response of S-19116 provides a critical time window for the protection circuit, increasing the fault interception rate to 99.97%.

2. Power consumption limitation deployment scenarios

The current detection IC with a power consumption of 6 μ A+forces BMS to add a $1.2 power management chip to each module. The 2 μ A current of S-19116 can be directly powered by MCU, reducing system costs by 18%.

3. Space occupation restricts integration degree

The traditional SOT-23 packaging occupies 9mm ², which restricts the integration of domain controllers. The PCB space released by the HSNT-6 package can accommodate additional temperature sensors or redundant circuits.

Application scenarios and business prospects

Technological Evolution: ABLIC's Next Strategy

1. Function integration: In 2026, a three in one chip with integrated overvoltage/undervoltage/reverse protection will be launched, reducing peripheral devices by 30%

2. Intelligent diagnosis: implanted AI prediction algorithm, warning of overvoltage risk 10ms in advance (patent JP 225-023456)

3. Voltage withstand upgrade: Develop a 60V voltage withstand version that is compatible with megawatt level ultra fast charging platforms

Conclusion: Redefining the 'impossible triangle' of automotive safety chips

The ABLIC S-19116 series breaks through performance boundaries with μ s level response, μ A level power consumption, and millimeter level packaging synchronization. Its value lies not only in leading parameters, but also in restructuring the design paradigm of in vehicle safety chips - when the "impossible triangle" of speed, energy efficiency, and volume is disrupted, the high-voltage system of electric vehicles will enter a new era of safety and controllability. With the popularization of 800V architecture and the improvement of domain controller integration, ABLIC chips with Japanese automotive grade quality may become the safety foundation for global intelligent electric vehicles.