SABIC develops and verifies a thermal runaway barrier scheme for two wheel electric vehicle batteries

2023-10-26

Global manufacturers, especially those in India and China, increasingly need to address the fire safety issues of two wheel electric vehicle battery systems. After a fire accident occurred in a two wheeled electric vehicle, the industry is looking for better solutions, especially since the current solutions all have the problem of phase change material leakage, which is not ideal.

Saudi Basic Industries Corporation (SABIC), a globally diversified chemical enterprise, utilizes existing STAMAX ™ Flame retardant resin technology has developed a new thermal runaway (TRA) barrier scheme to improve the fire safety of two wheeled electric vehicle batteries.

When this thermal runaway barrier layer containing FR STAMAX resin encounters open flames or high heat, it will immediately form small dents similar to coke. Within a few minutes, these charcoal like additives will form an expansion layer, serving as a barrier for the battery cell. This means that if one battery cell is damaged, the fire will not spread, while the other cells will remain intact.

UL testing

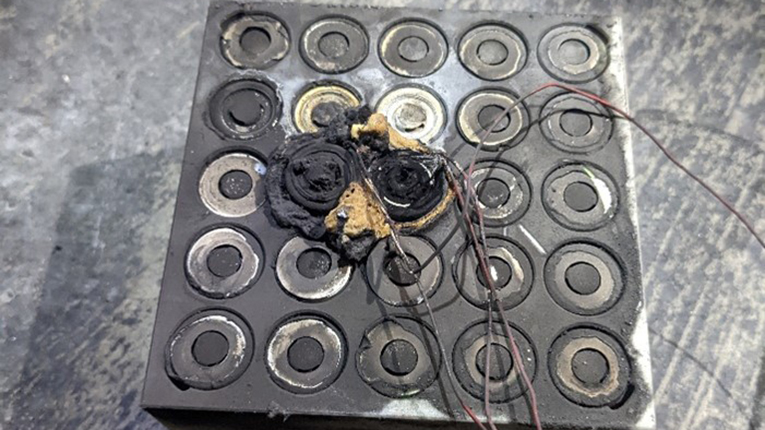

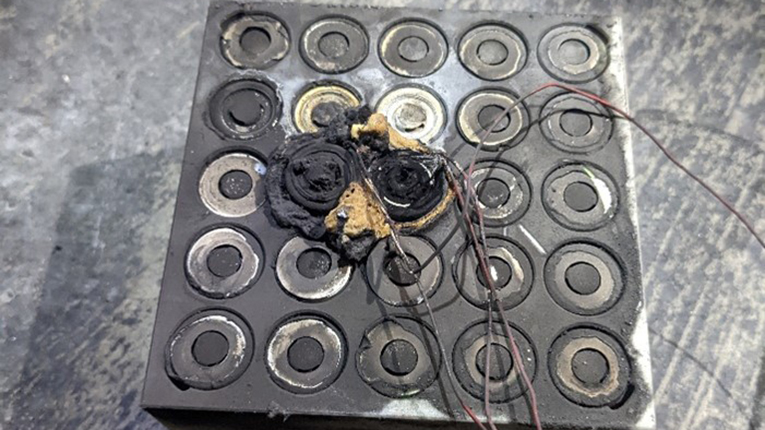

SABIC collaborated with Underwriters Laboratories (UL) to test thermal runaway barrier schemes to verify their performance. The test involves placing 25 standard 18650 cylindrical cells in a box, separating them with a 2mm thick FR STAMAX 30YH570 resin barrier layer, and then triggering the two cells in the middle to cause heat loss.

Subsequently, observe the damage of the remaining 23 battery cells. It was found that these cells were able to work safely without thermal penetration or damage.

The heat resistance and mechanical properties of SABIC FR STAMAX 30YH570 resin under thermal runaway conditions have obtained UL's official certification mark.

Advantages for partners

SABIC's unique injection molding and single piece thermal runaway barrier solution provide many advantages for electric vehicle batteries, including:

Easy to disassemble

Easy to manufacture, suitable for mass production, with a production cycle of less than one minute

Easy to expand, suitable for columnar batteries of various sizes and capacities

Compared to traditional metals, it is lighter in weight

• Reduce costs

• Reduce weight

Improve fire safety

Thermoplastic solutions are easy to recycle

About SABIC

Saudi Basic Industries Corporation (SABIC) is a world-renowned diversified chemical enterprise headquartered in Riyadh, Saudi Arabia. The company's manufacturing factories are located worldwide, including multiple countries and regions in the Americas, Europe, the Middle East, and Asia Pacific, with products covering chemicals, general and high-performance plastics, agricultural nutrients, and steel.

In key terminal application markets such as construction, medical equipment, packaging, agricultural nutrients, electronics, transportation, and clean energy, SABIC has long been committed to helping customers explore potential opportunities.

In 2022, SABIC's net profit reached 16.53 billion rials ($4.41 billion), achieving a total sales revenue of 198.47 billion rials ($52.92 billion). As of the end of 2022, the company's total assets reached 313 billion rials ($83.46 billion). In 2022, the total production of SABIC reached 61 million tons.

SABIC operates in approximately 50 countries worldwide and has over 31000 employees. Adhering to the spirit of innovation and original thinking, SABIC has a total of 10090 patents and pending applications under its umbrella. The company has abundant scientific research resources and has innovation centers in five core regions: the United States, Europe, the Middle East, South Asia, and North Asia. For more information, please visit www.sabic.com.