The warehouse management of electronic components trading industry is generally time-consuming, error prone, messy and inefficient. The following factors are common:

1. Electronic components are calculated according to the number of purchased products and small packages. The number of copies, input product code, batch number, small package quantity and other label elements are required for each product. The circular operation is time-consuming and error prone.

2. The replenishment personnel can't grasp the shortage situation in the picking area, so they can only find the warehouse and replenish again. The replenishment efficiency is low

3. The management system in the warehouse has been continuously improved, but it can not be implemented. For example, there are no goods in the picking area, and the replenishment personnel do not want to wait to pick up the goods directly from the whole area, resulting in chaos on both sides.

In view of the time-consuming and chaotic situation of warehouse management in the electronic component trade industry, ERP warehouse management system, through PDA combined with bar code label management, makes the warehouse management orderly and greatly improves the work efficiency.

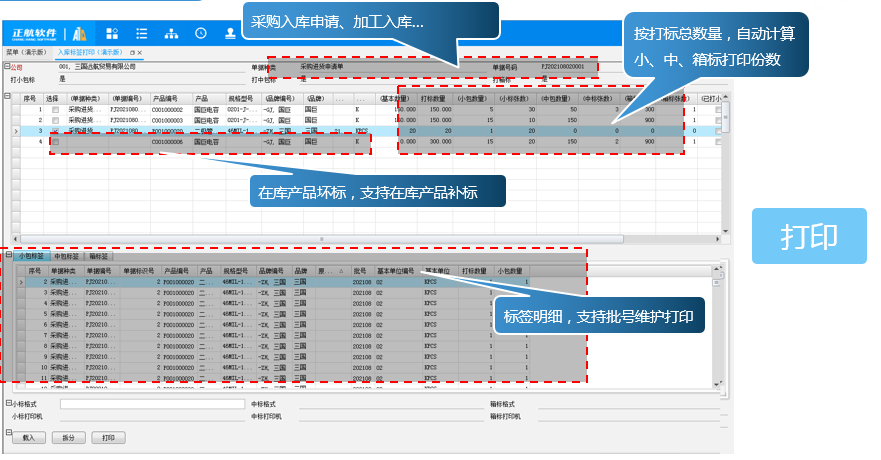

Unified management of bar code labels

The unique barcode label of the product printed in the specified format includes the minimum package barcode label, medium package barcode label, box barcode label and other unified labels, which lays the foundation for the warehouse to realize the whole process intelligent barcode.