The car’s intellectualization speeds up and Roma builds a high wall for safety

2022-09-17

A new round of global technological and industrial revolution is coming quietly. Electrification, networking, intelligence and sharing have become the development trend and trend of the automobile industry. Driven by the new four modernizations of automobiles, the automobile electronic and electrical architecture has gradually evolved from the original distributed architecture to the cross domain centralized architecture and the vehicle centralized architecture. The automobile electronic software architecture has been continuously upgraded, and the software and hardware are layered and decoupled. The era of software defining automobiles is coming. With the acceleration of automobile intellectualization, China's new energy vehicle market is improving, the carrying rate of ADAS functions is rising, L2 is becoming the standard configuration, and L3 is starting to be mass produced.

Functional safety becomes the focus of the industry under the trend of automobile intelligence

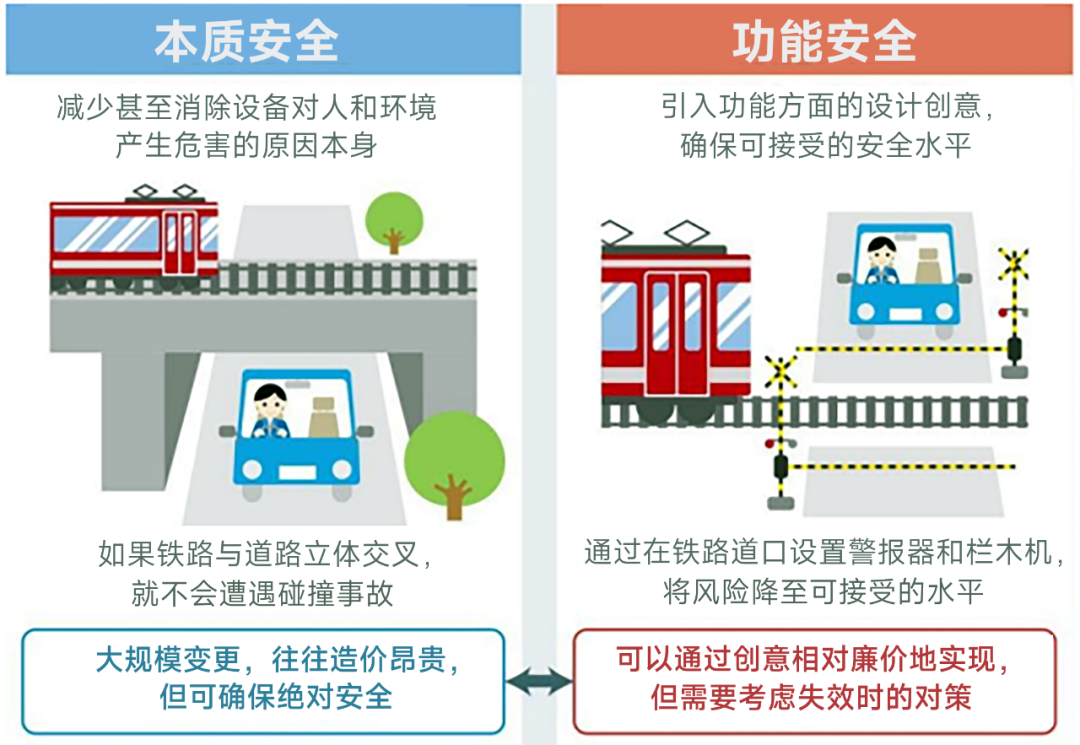

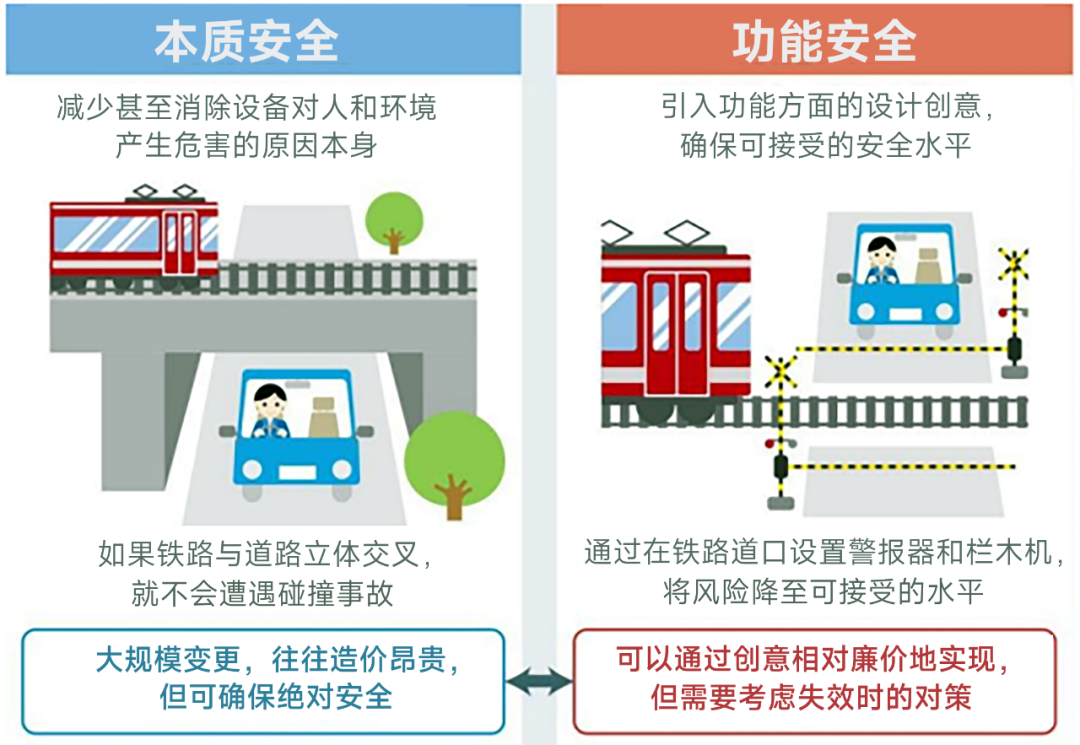

With the promotion of automobile intelligence and the rapid change of automatic driving technology innovation, safety has become the focus of the industry. There are two kinds of safety, one is intrinsic safety, the other is functional safety. Intrinsic safety is a method to ensure safety by eliminating dangerous causes; Functional safety is a method to ensure safety by reducing risks to an acceptable level through functional efforts. Intrinsic safety can ensure absolute safety, but the cost is often high; In contrast, the cost of functional safety is low, but the design must consider how to ensure safety when additional functions fail.

Figure | Intrinsic safety and functional safety ideas

Figure | Intrinsic safety and functional safety ideas

For example, at railway and road intersections, if the method of building overpasses is used to separate the railway from the road and physically avoid the collision between trains and cars, it is an intrinsically safe idea. However, if alarms and railings are set at the intersection of roads and railways, and sensors are installed on the railways, when the sensors detect that trains are approaching, the alarms will sound and the railings will be lowered; when other sensors detect that trains have passed, the alarms will stop and the railings will be raised, although the roads and railways are still physically crossed, However, the risk of collision between cars and trains can be reduced to an acceptable level by setting railway crossings, which is the idea of functional safety. Of course, in this case, if the sensor is damaged, the alarm and railing will not work when the train is approaching, which is a "dangerous" state. Therefore, it is necessary to add the self diagnosis of the sensor or the redundancy design of dual sensors to ensure that the design of a dangerous state will not be triggered even if the sensor is damaged. This is the idea of Fail Safe.

It can be seen that functional safety is actually a design based on the idea of "people will make mistakes" and "things will be damaged". Functional safety usually takes into account both "systematic failure" and "random failure" to ensure that there is no systematic bug and that random failure will not cause harm to people. In China, ISO 26262 (functional safety) has been included in the recommended national standard, and the first Chinese version of ISO 26262, GB/T 34590, has been implemented since May 2018.

Of course, not only the automotive industry has this requirement, but also many industrial scenarios have very high requirements for safety. In order to build a safer system, it is necessary to consider how to ensure safety in case of problems during equipment development, which means that fault safety and functional safety run through the whole process of equipment development.

Reset IC to ensure the safety of automobile and industrial equipment

When it comes to the requirements of automobile and industrial application scenarios for equipment safety, we have to mention the importance of monitoring the system power supply voltage. Reset IC is one of the indispensable products in the voltage monitoring circuit, and has been widely used in EV/HEV inverter, engine control unit, ADAS, automobile navigation system, automobile air conditioner, FA equipment, measuring instruments, servo system In various vehicle and industrial equipment applications that require voltage monitoring of electronic circuits, such as various sensor systems.

In response to the market demand, Rom launched more than 1000 reset ICs. In 2021, it created an annual shipment record of 250 million pieces in the wide application field of low voltage range. Just recently, Rom has also developed a window reset IC "BD48HW0G-C" with high precision, ultra-low power consumption and support for 40V voltage.

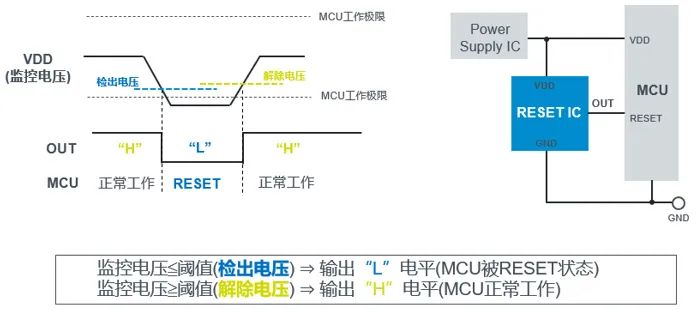

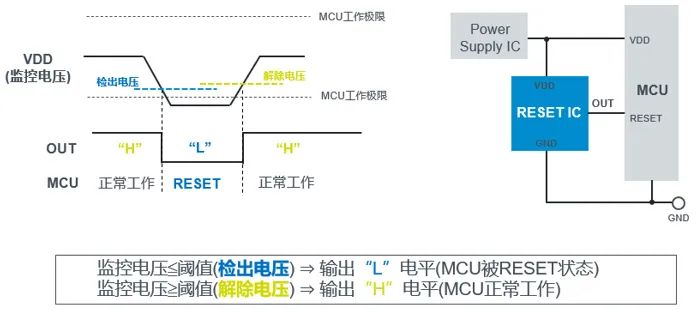

Figure | Example of reset IC operation

Figure | Example of reset IC operation

What is reset IC? The reset IC is a switching IC that can be used for voltage monitoring of electronic circuits. When it detects that the monitored voltage exceeds the threshold value, it will achieve the effect of reset operation by changing the output. Therefore, it has the function of ensuring system safety by cooperating with the microcontroller. Just like the water level alarm in the river, when the river water overflows the highest warning line or is lower than the lowest warning line, the alarm will be sounded, and the water discharge or storage action will be triggered. The water level sensor here is just like the reset IC in the circuit, which has the same effect.

What's special about Rom's new reset IC "BD48HW0G-C"?

Why are there so many types of reset ICs? What are the features or advantages of Rom's latest reset IC "BD48HW0G-C"? Due to different application scenarios, the system circuit has different requirements for reset IC accuracy, power consumption, operating voltage, functional safety, monitoring voltage range, undervoltage/overvoltage detection, etc., so different reset ICs need to be developed to match the corresponding market demand.

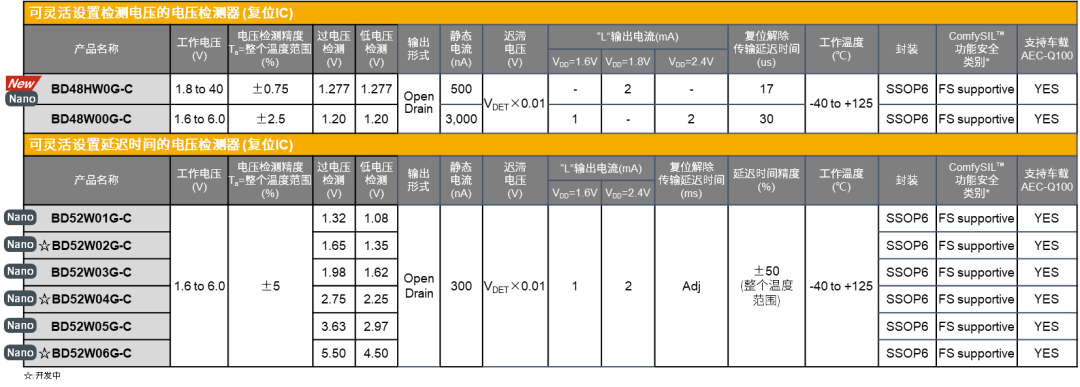

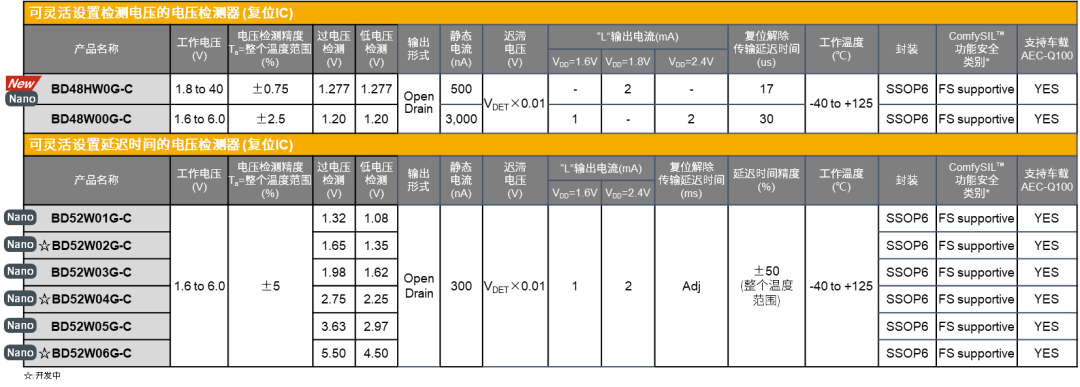

Rom window reset IC product lineup:

Nano labeled product is equipped with Nano Energy ™ Ultra low quiescent current technology products.

*FS supportive: It indicates that this is an IC developed for the vehicle field and supports safety analysis related to functional safety.

Rom's latest reset IC "BD48HW0G-C" is a window type reset IC that supports 40V voltage. Due to the adoption of the high voltage withstand BiCDMOS process and the integration of the analog design technology Rom is good at, the BD48HW0G-C has an adjustable operating voltage range of 1.8V~40V. As for the window type design, BD48HW0G-C is equipped with two independent reference voltage circuits, so the high side and low side detection voltages can be flexibly set, and the detection output can be reset independently. In terms of detection accuracy, BD48HW0G-C can achieve the industry's advanced ± 0.75% voltage detection accuracy within the temperature range of - 40 ℃ -+125 ℃, which is higher than the accuracy of industry standard products by ± 2.2%. In terms of power consumption, the quiescent current of BD48HW0G-C is only 500nA, which is only 1/16 of the window reset IC with an ordinary operating voltage of more than 24V. This allows engineers to design circuits without worrying about the increase in power consumption caused by reset circuits.

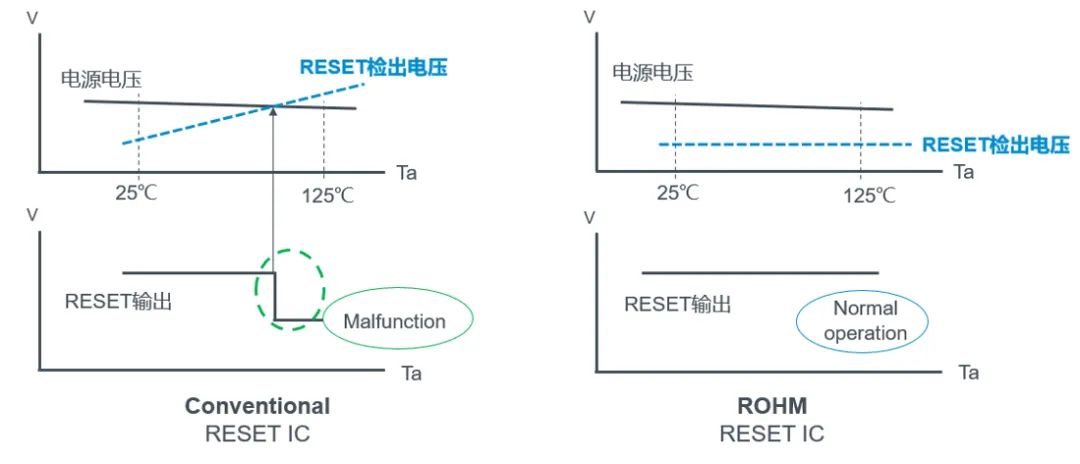

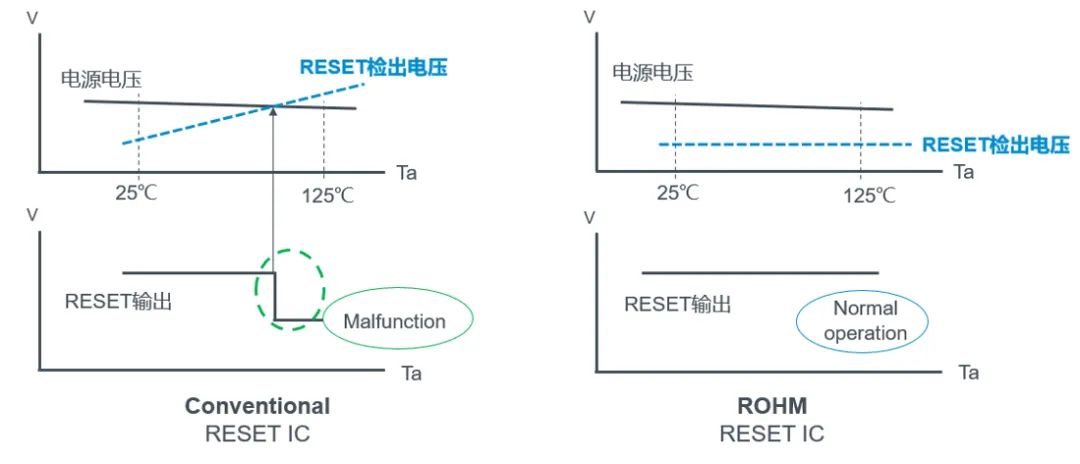

Figure | High precision reset IC in the full operating temperature range is easier for system design

Figure | High precision reset IC in the full operating temperature range is easier for system design

Why should we emphasize the stable and high-precision characteristics in the full operating temperature range in the vehicle and industrial fields? We know that if there is only a problem of value deviation at 25 ℃, it can be adjusted through fixed compensation, which is easier to achieve. However, in automotive and industrial applications, the ambient temperature and the body's own heating and cooling conditions are quite different. The power supply voltage and reset detection voltage will fluctuate under the influence of temperature. This deviation under the influence of temperature is very difficult to correct. Therefore, for vehicle and industrial environments, it is easier to select a stable high-precision reset IC within the full action temperature range for system design, thus reducing the design burden of customers. In addition, in vehicle mounted and industrial environments, the environment noise is usually large. When external noise invades, if the voltage is detected to be of poor accuracy, misoperation is likely to occur. Therefore, in order to avoid or reduce the impact of external noise and improve the reliability of system operation, high-precision complex IC is a better choice.

It is worth mentioning that Rom has been building the process of ISO 26262 since 2015, and in March 2018, about two and a half years later, he passed the T? V Rheinland has obtained the process certification of ISO 26262. Just because he has a high understanding of the ISO 26262 specification and application circuit, Rom has developed a reset IC that supports a wide range of voltages from low to high and detects voltage anomalies with high accuracy for vehicle and industrial control power supplies that require functional safety.

The Secret Nano Energy to Achieve Ultra Low Power Consumption of Analog Power Devices ™

As mentioned earlier, the static current of BD48HW0G-C is only 500nA, which is only 1/16 of the window reset IC with an ordinary operating voltage of more than 24V. How can such ultra-low power consumption be achieved?

In fact, Rom adopts the IDM mode. Under this vertical integrated production system, Rom has deeper experience accumulation and stronger simulation technology advantages in "circuit design", "layout" and "process". Based on this, Rom has developed the epoch-making technology "Nano Energy?" to completely reduce the current consumption under ultra light load. With this technology, the quiescent current at no load can be as low as nanoamperes (nA), which can not only extend the driving time of battery powered IoT devices and mobile devices, but also help the efficient operation of vehicle mounted and industrial devices that do not want to increase power consumption.

For example, we know that new energy vehicles are an important part of the global "dual carbon plan". For EV/HEV, it is imperative to improve fuel economy and increase driving mileage, so low power consumption will become particularly important. Secondly, when the car stalls at idle speed, the engine will stop running, and the battery will provide the power required for functions. Moreover, when parking, the clock will run in the background, the alarm system will be turned on, the keyless system will be turned on, etc., which will be directly powered by the battery. There is a risk that the battery will run out. Therefore, it is just necessary to further reduce the current consumption of the power supply IC, and the Nano Energy? Technology can contribute to the low power consumption of the whole automobile system. In addition, low quiescent current brings not only a benefit of extending the life of battery powered equipment, but also a benefit of reducing the dark current in the circuit for automotive and industrial applications, contributing to the improvement of EMC.